Electricty Tower IOT Structural Monitoring

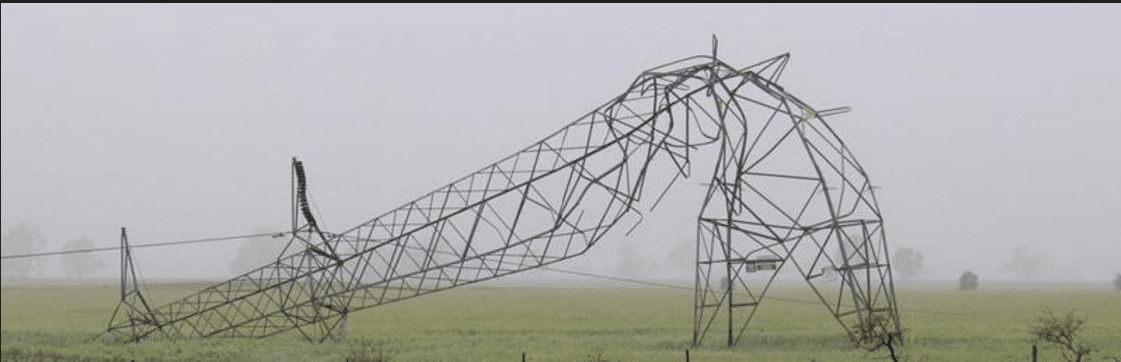

For electricity utility companies the biggest form of outages of their network comes from supply towers failing.

Although utility companies monitor the changes in electricity transmission, collection of customer data and the downtime of their sub stations and network but there is limited data collection of their towers physical condition.

This article will go over 2 methodologies of monitoring the standard Australian Electricity supply towers all across your network.

When it comes to physical condition monitoring of towers there is a tedious way this is completed by utility supply companies.

Usually an in person inspection is required but this is a difficult exercise and hard to complete on all towers within a utility supply chain as most towers are inaccessible because of their installation location & terrain.

In addition the sheer number of towers within a network it would require vast man power to complete this exercise.

Additionally monitoring the condition of the physical structure in person is a difficult task with multiple different pieces of equipment required to gather movement data and a deep analysis and understanding of the structure is required.

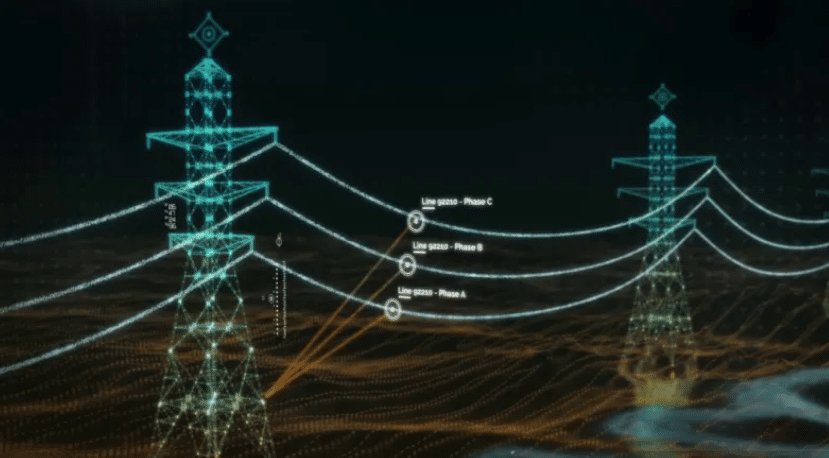

Wireless IOT Monitoring Sensors

A Move Solutions monitoring package for monitoring Utility towers is the simpliest, most affordable and easiest solution on the market.

With installation of the sensors only taking a few minutes and a LoRaWAN Coverage network wide enough to cover the whole network of your utility network, we can monitor the condition of hundreds of towers remotely while gathering a huge data set of structural information.

Proposed Solution

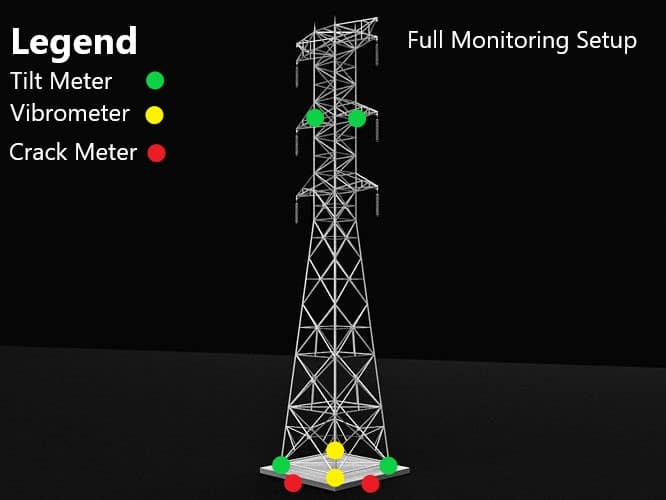

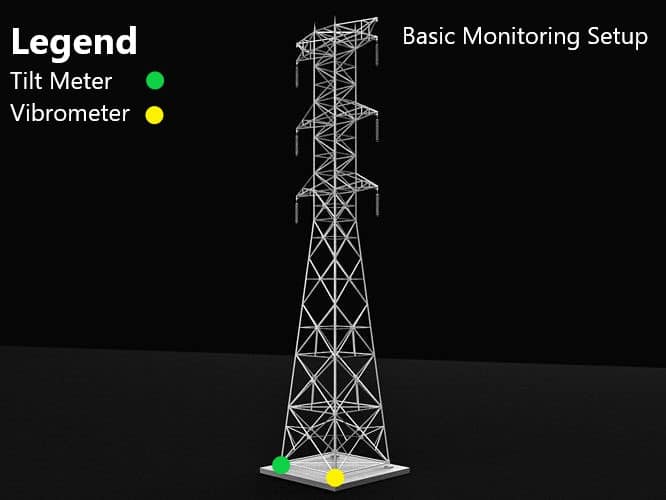

Below are 2 options a complete setup and a basic setup, both options provide the required structural information to be able to determine the change in physical condition of an asset and an early warning detection to enable you to complete a site investigation and carry out remedial works.

The Complete monitoring solution will provide you with a full picture of your assets structural health information.

The tilt sensors placed at the bottom and top point of the tower will provide angular change at the base of the structures support and how much deflection is being caused at the top.

This will allow you to calculate the failure point of the steel used for construction of the tower and predict a collapse before it would occur.

Additionally vibrometers will provide you with an early warning detection system of foundation cracking and settlement that may be occuring.

Couple this with crack sensors on the base and you have a complete picture of the foundation support and its health status which could lead to a failure of the upright.

The Basic monitoring solution is a cut down and more affordable version of monitoring electrical towers.

This solution provides you with the tilt variation of the lower support and will be able to determine if the support is tilting under stress more rapidly overtime.

The vibrational analysis will provide an early warning system for the deteriation of the foundation the footings are mounted into and allow a visual site inspection to be undertaken or a full monitoring solution to be installed to gather further data from the structure.