Ultrasound Measuring Instrument Trotec SL800

with the Ultrasound Measuring Instrument Trotec SL800 even the smallest leaks in compressed air ducts lead to increased friction when gas leaks, which produces non-audible noises in the ultrasonic frequency range.

In the same way, wear and tear on movable machine components is noticeable at an early stage.

These sound waves caused by flow friction are received by the probe of the SL800R and are transformed by high-performance transducer technology into the audible sound, which is played on the sound-insulated headphones and additionally displayed as an indicator value via a ten-segment LED bargraph.

The combined visual and audio recording with adjustable headphone volume allows concentrated work even in low light conditions and with ambient noise.

For leak testing of pressureless systems such as tanks, containers or air chambers and ventilation systems, the SL800T transmitter is also included in the set for its application to ultrasound.

Here are some benefits in practice:

- Development, design, manufacturing: 100% Trotec

- Easy detection of smallest leaks

- Point-accurate leak detection by high-performance sound transducer technology

- Cost-effective leak detection on compressed air ducts as well as steam, gas and vacuum systems, boilers, liquid-carrying pipes, valves, slides, and steam traps

- Reliable early detection of sliding and rolling bearing damage or other wear noise

- Air and body probe for a wide range of tasks

- Location even in ambient noise thanks to high-quality, sound-insulated headphones

- Easy to use

Ultrasonic detection with the SL800 set offers you a wide range of possible applications:

SL800R with body probe

- Early wear detection on ball, roller or plain bearings

- Check of centrifugal pumps for cavitation

- Sealing control of fittings

- Continuity and functional testing of steam traps

This probe uses the body sound as a carrier of internal states and processes. Thus, the device combination acts like an electronic stethoscope.

SL800R with air sound probe

- Leak detection on exposed pipes

- Leakage-induced loss detection of gas-filled pipeline networks even during operation

- Detection of leaks in high pressure steamers

- Localization of hairline cracks, poor weld seams or worn flange connections

- Leak detection on all accessible fittings and connecting elements in which processes are carried out under vacuum or high pressure

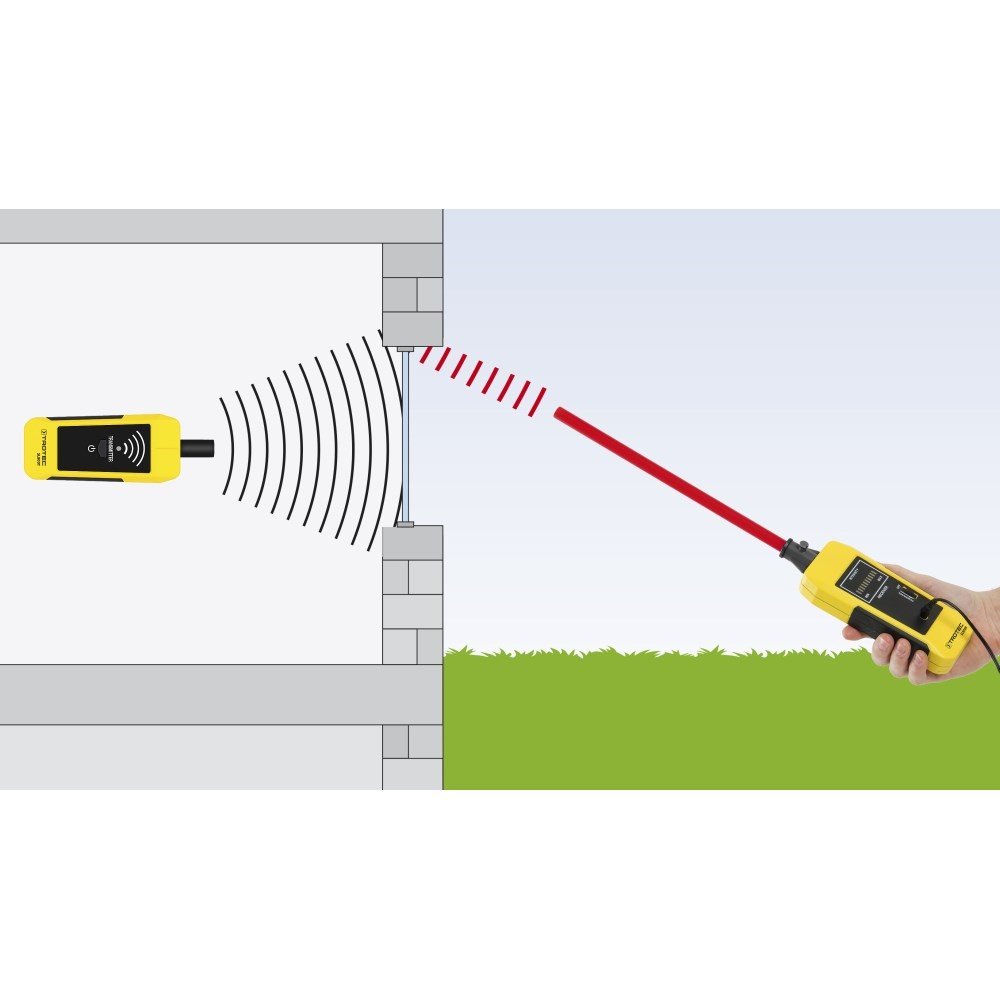

SL800R with airborne probe and ultrasonic transmitter SL800T

- Leakage test for determining the cause of energy defects, for example on building doors or windows

- Testing of containers, casings or climatic chambers for leaks

- Ultrasonic treatment of tanks or containers for testing sealing components

Here are some technical details::

- Ultrasound (Digits): Reception frequency (kHz): 36 – 44 / Transmission frequency (kHz): 40

- Display: Function LEDs, 10-step LED bar display

- Power supply via battery (2x 9V block battery)

- Interface: 3.5 mm jack (for headphones)

- Working temperature: Operation (°C): 0 to 40, Storage (°C): -10 to 50

- Device control: buttons, thumbwheel

- Housing: plastic

- Dimensions (length x height x width): 430 x 120 x 325 mm

- Weight: approx. 1064 g

Get in touch