How to ensure building structural safety

Buildings can gradually accumulate damage and deteriorate during their operational lifetime, due to material aging, seismic events, design errors, unforeseen foundation settlement, etc.

Regular structural monitoring is therefore the key in order to design a maintenance plan and ensure safety and serviceability.

These are the parameters that should be monitored on buildings:

- Dynamic parameters (vibration, acceleration)

- Static parameters (inclination, static displacement)

- Modal Parameters (frequencies, shapes and damping)

- Environmental Parameters (structure and air temperature, humidity, wind, rainfall)

- Geotechnical parameters (ground slope, groundwater level, precipitation, cracks etc.).

They all need to be checked at some point, however they do not always need to be monitored at the same time: it depends on the project. We have created three main types of monitoring systems for buildings and vertical structures: basic, full and extra. They are only guidelines and they can change according to the needs of the specific structure and project: however they will help you have a clearer idea on what is the kind of monitoring system that your structure might require.

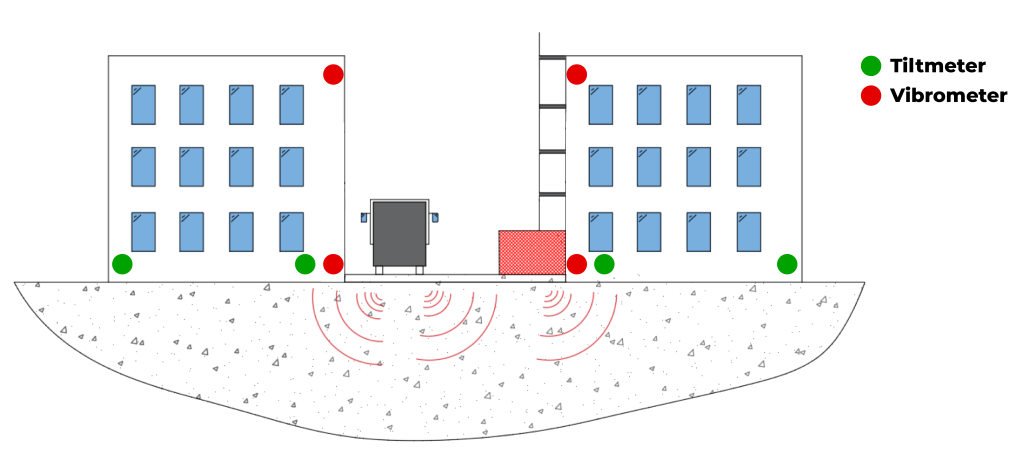

Basic setup: Tiltmeters & Vibrometers

Basic SHM setup system for buildings and vertical structures

Tiltmeter

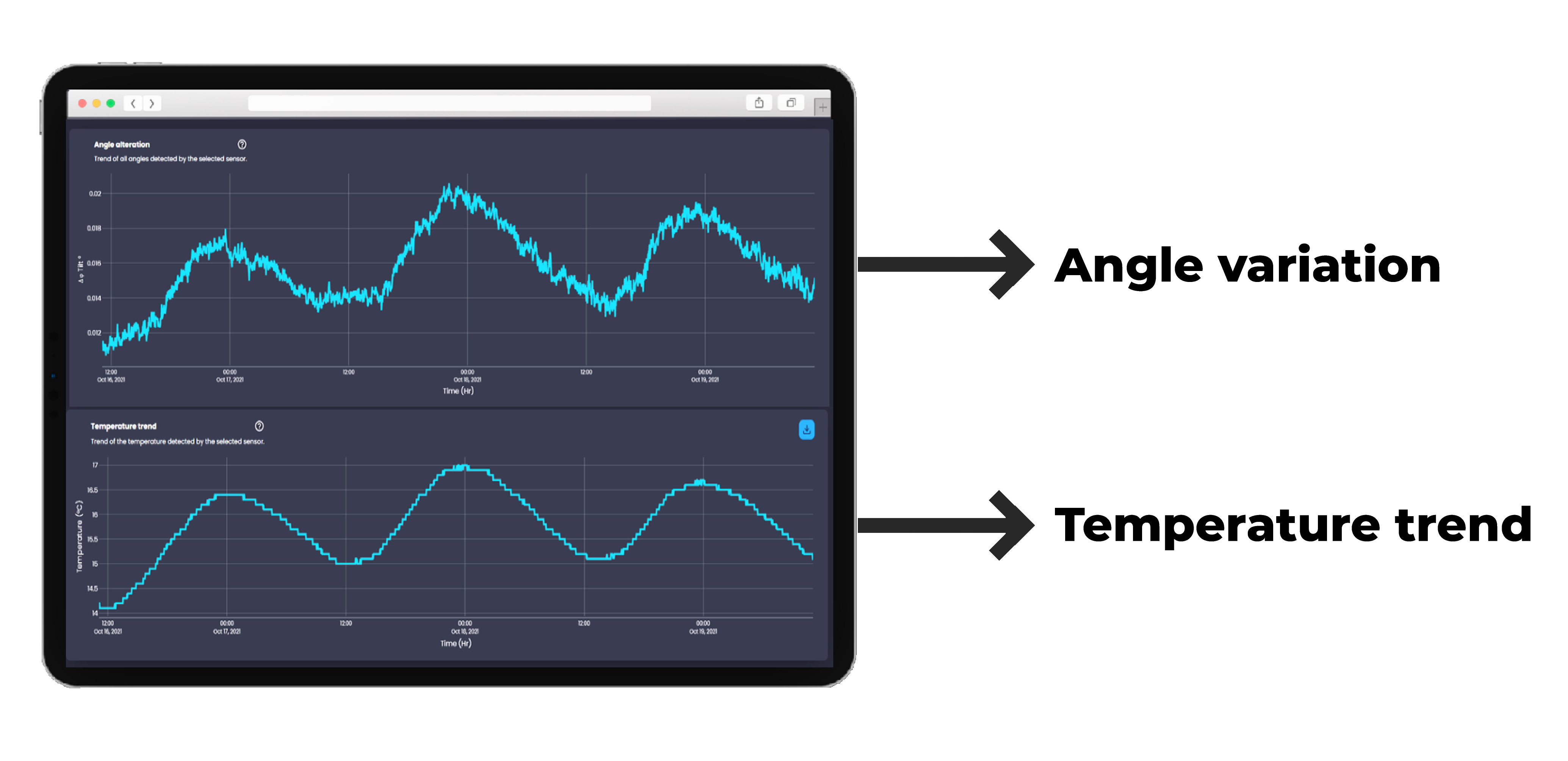

A Tiltmeter measures the angle of inclination (tilt) of the point where it is installed. which helps understand whether there is any land subsidence occurring that puts the stability of the structure at risk. This is part of what we call “static analysis”. All Move Solutions sensors also measure temperature, which is useful to understand how much the structure and material expands or contracts with changes in daily/ seasonal temperature.

Move Solutions Cloud Platform showing data from a tiltmeter

Vibrometer

A Vibrometer is used for dynamic analysis: it evaluates how the structure reacts to external stress, thanks to frequency and vibration analysis and to Peak Particle velocity (PPV). Our vibrometers also have a threshold setup option in line with the current legislation of your country (DIN4150, UNI9916, BS7385*, SN 640 312a*, RI8507*), sending real-time alerts in case of anomalies.

Move Solutions Cloud Platform showing data from a vibrometer

full set up

The Full Setup monitoring system allows to monitor both static and dynamic structural parameters, for short and long-term projects.

- Tiltmeters

- Vibrometers

- SHM Accelerometers per floor

- Analog node + Crackmeter.

We have already explained the use of Tiltmeters and Vibrometers. Let’s now look into what an accelerometer and an analog node could add to our Structural Health Monitoring system.

Full SHM setup system for buildings and vertical structures

SHM Accelerometer

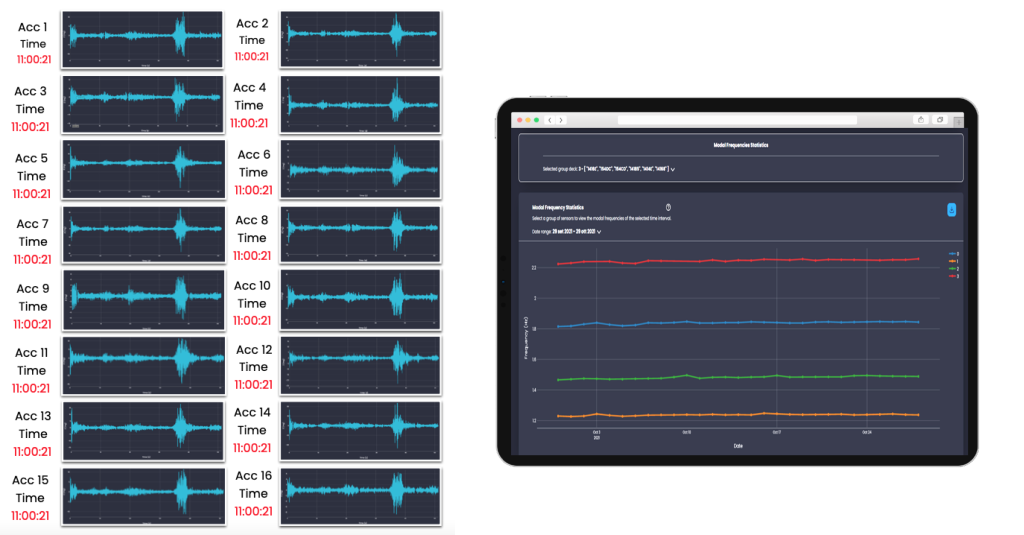

An Accelerometer is used to monitor dynamic parameters such as triaxial acceleration, frequencies, modal shape and damping. Our SHM Accelerometers are unique on the market because they are the only devices to monitor acceleration that are both wireless and synchronisable: that allows you to have a much more accurate analysis of your structure without costly installations with cabled sensors. Synchronized sampling can be set at an interval of one every 1h, 2h, 6h, 12h or 24h. Thanks to this synchronization it is possible to do a complete Operational Modal analysis of the building both for frequency and shape.

(To know more about Operational Modal analysis watch this video – in Italian: https://www.movesolutions.it/2022/05/16/watch-the-webinar-operational-modal-analysis-for-shm/)

Similarly to our Vibrometer, with our SHM Accelerometer it is possible to have a threshold setup option, sending real-time alerts in case of anomalies.

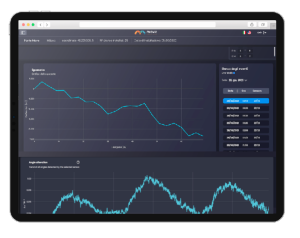

Move Solutions Cloud Platform showing data from sixteen synchronized accelerometers

Analog Communication Node + Crackmeter

The Analog Communication Node is a device that can be connected to any geotechnical sensor. With our Analog Nodes the communication with the Gateway is wireless and uses LoRaWAN protocol. If connected to a crackmeter it is possible to identify and analyze any crack in order to assure the integrity and the underlying durability of the structure. Other types of sensors and probes can also be connected to complete the system and satisfy any monitoring need.

Extra set up

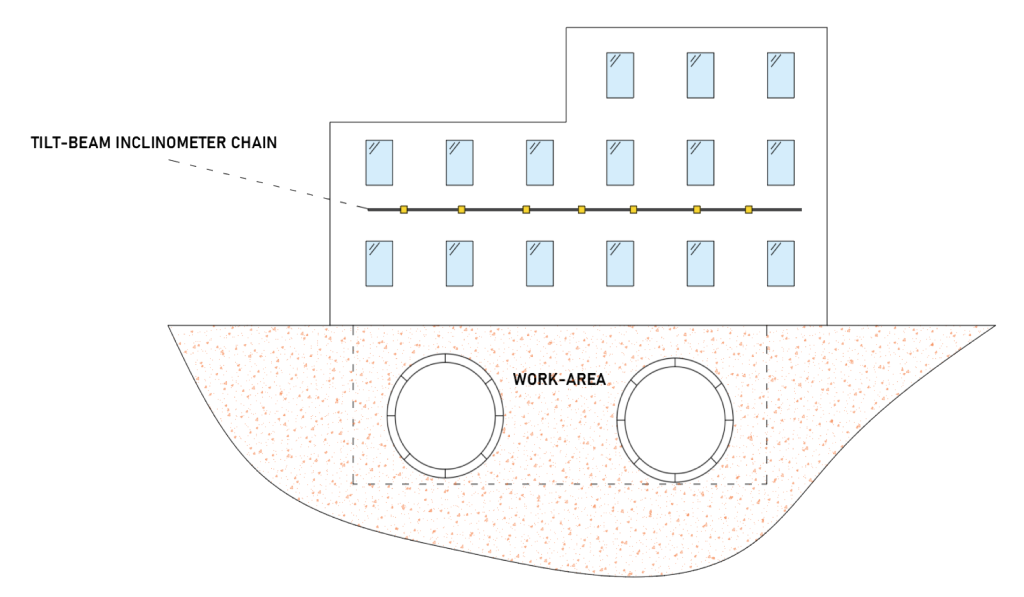

Tilt-beam inclinometer chain

Tiltmeters installed in series on horizontal tilt-beams allow to monitor the static balance of the structure and of the vertical subsidence caused by deterioration of the soil or by works in progress near the building (such as the construction of a tunnel).

Extra SHM setup system for buildings and vertical structures

Move Solutions Cloud Platform showing data from a tilt-beam inclinometer chain

Structural Health Monitoring is an important tool that helps:

- detect problems at an early stage

- enable a proactive response

- design cost-effective solutions

- optimize maintenance process

- avoid breakdowns

- boost the structure lifetime

- improve safety

- save lives.

Thanks to recent advancements in technology and to the development of Internet of Things (IoT) devices, all Move Solutions SHM systems can now be:

- cost-effective

- wireless

- low-power

- easy to install

- easy to read thanks to data processing platforms

- connected to a cloud platform that gives access to your data remotely.

Latest From Our Blog

Electricity Tower IOT Structural Monitoring

Electricty Tower IOT Structural MonitoringFor electricity utility companies the biggest form of outages of their network comes from supply towers failing. Although utility companies monitor the changes in electricity transmission, collection of customer data and the...

Different Types of SHM: Which one to Choose?

Different Types of SHM: Which one to Choose? Depending on the structure and on the need of the monitoring project, there are different types of structural analysis that can be done. They tend to be divided into two main groups: static analysis and dynamic analysis....

GNSS Test Orbit C620

Correction vs Non Correction DataThe Difference Between Correctio & Non Correction DataWe decided to put the Compact C620 Under a corrections test. This test was based around understanding how well the GNSS Receiver performed without correction on a known...

Contact us today

Weekdays

8:00 PM -5:00 PM

Contact

Phone

08 8340 7888

info@codycorp.com.au

Address

28 Islington Court,

Dudley Park, SA, 5008